CNC Machining

1-10000 pcs

3/5 axis machining

3-20 working days

CNC Machining

1-10000 pcs

3/5 axis machining

3-20 working days

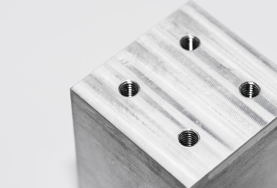

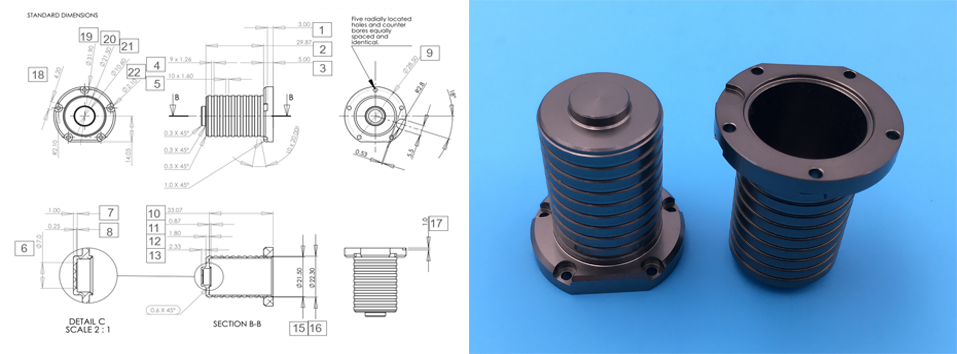

CNC Machining Serivce

At SINO MFG, we use advanced equipment to offer you a variety of CNC machining services including CNC turning, CNC milling, EDM and wire EDM, surface grinding and much more. Using our imported 3 and 5-axis CNC machining centers, our skilled machinists can make CNC machined parts using a wide range of plastic and metal materials. Our CNC machining abilities making us a great one-stop-shop for your advanced designs. Contact our team for a free quote and to discuss which process is the right one for your next project.

What Is CNC Machining?

CNC machining is a subtractive manufacturing process, where raw material is removed with a variety of precision cutting tools to make components. Advanced software is used to control the equipment according to the specification of 3D drawings. CNC machining is the best choice for rapid prototyping of high quality metal and plastic parts, suitable for parts that require ultra-high dimensional accuracy, strict surface finish, and specific material properties.

Advantages Of Our CNC Machining Services:

CNC machining is great to meet a range of your product development needs. Here are some of the benefits of SINO MFG CNC machining services:

- Wide range of materials selection

- Able to maintain strict tolerances

- Low investment in tooling or preparation costs

- According to the order, the standard delivery cycle is 5-12 working days (Running time of our CNC machines is 7*24 hours)

- Our CNC machining cost is RMB 60/hr, and usually the CNC machining cost of CNC manufacturers in the United States is $60/hr

CNC Machining Process

CNC Turned Parts

Our CNC lathes enable high speed and high-quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores to be generated. Our turning capacity is available for one-off prototypes through to low-volume production of your product and parts.

CNC Milled Parts

CNC milling is used to apply a machined surface finish on plastic or metal or for creating complex 3D shapes. We use domestic and imported 3 and 5-axis CNC machining centers with quick-change tooling, programmed using advanced Delcam software.

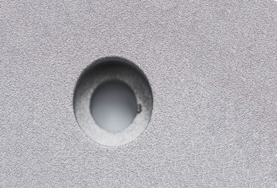

EDM / Wire EDM And Surface Grinding

EDM (electrical discharge machining) is a method for cutting holes, pockets, and other shapes into hardened steel, as well as imparting a surface texture to the internal cavities of mold tools. A sacrificial electrode in an electrolyte bath discharges a high-powered electric spark to erode very hard materials that would be difficult or impossible to do with any other method. Square pocket holes are often created with this method.

With wire EDM, a copper wire is continuously fed between two spools. When electrically charged, it’s able to cut through hardened tool steels quickly and accurately.

At SINO MFG, we also offer surface grinding services. When surface grinding the workpiece is held stationary on a horizontal plate. The surface grinding wheel is computer controlled to abrade the workpiece to a precise depth.

CNC Machining Tolerance

Our general tolerances for CNC machining is:

- Standard +/- .05 mm

- Minimum +/- .002 mm (metal), +/- .003 mm (plastic)

Tolerances are greatly affected by part geometry and type of material. Our project managers will consult with you on every part of your project and will seek to provide the highest degree of precision possible.

CNC Parts Materials

Through continuous technological innovation and development, we have accumulated a very rich and wide range of various types of metal and plastic materials machining process characteristics and technical know-how. In addition to our stock list, we can provide you with customized raw material as required.

| Steel, iron series | Stainless steel series | Aluminum series | Copper series | Plastic series | Surface treatment |

| SUM24L | SUS303 | AL1050 | C1020 | PC | Sand blasting |

| SUM23 | SUS304 | AL2017 | C1100 | PP | Anodizing |

| SS400 | SUS316 | AL2024 | CuCr | Nylon | Nickel plating |

| S45C | SUS403 | AL5056 | CuTi | POM | Titanium coating |

| SCM435 | SUS416 | AL5052 | C5191 | ABS | Gold plating |

| SKD11.61 | SUS420J2 | AL6020 | C1220 | PVC | Silver plating |

| SK3、SK4 | SUS430 | AL6061 | C3604 | PEEK | Chrome plating |

| Others | SUS630 | AL6063 | Others | PMMA (Acrylic) | Black oxide |

| Others | AL6082 | PTFE (Teflon) | Polishing | ||

| AL7075 | Bakelite | Chemical grinding | |||

| Others | Others | Others |

Surface finishes

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the CNC machined parts.

| Picture | Name | Description |

|

Smooth (as machined) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. |

|

Sand Blasting | Sand blasting adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Mainly used for aesthetic purposes. |

|

Anodized Clear or Color (type II) | Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance. Available in a variety of colors. |

|

Anodized Hardcoat (type III) | Hardcoat anodizing produces a thicker ceramic coating providing excellent corrosion and wear resistance. for functional applications. |

|

Powder Coated | Powder coating adds a thin layer of strong, wear and corrosion resistant protective polymer paint on the surface of a part. Available in a large range of colors. |

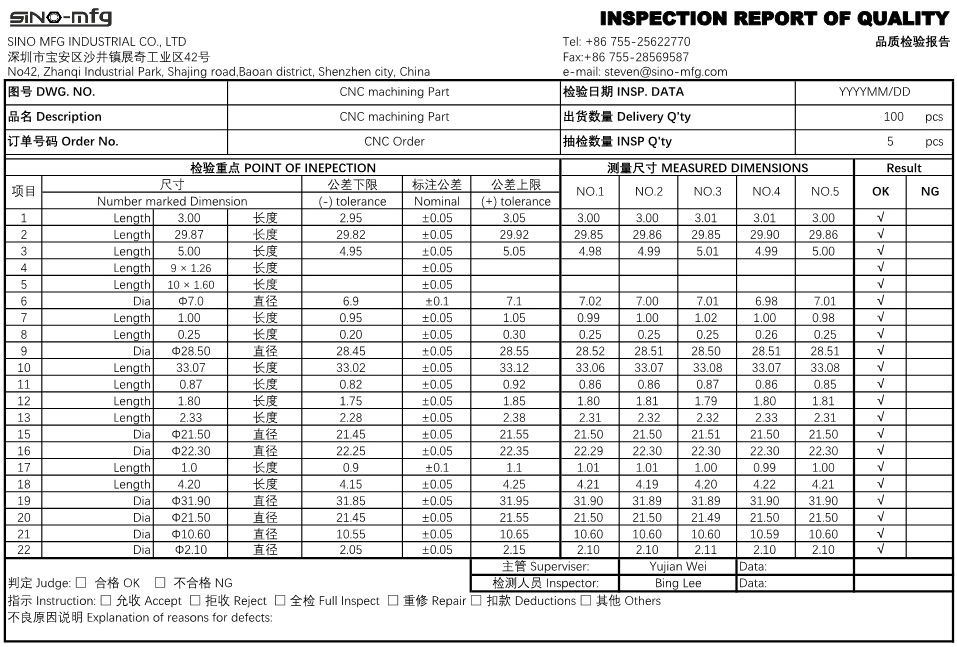

QC report

After the parts have been CNC machined and surface treated, we will use professional QC equipments to inspect the parts and send relevant QC reports according to customers’ requirements.

Please click on our RFQ page for reference on how to request an inquiry. We will provide custom quotation within 12 hours.

Bring your product idea to life as soon as 5 days!

Bring your product idea to life as soon as 5 days!

Bring your product idea to life

as soon as 5 days!