CNC Milling

1-10000 pcs

3/5 axis machining

3-20 working days

CNC Milling

1-10000 pcs

3/5 axis machining

3-20 working days

CNC Milling Service

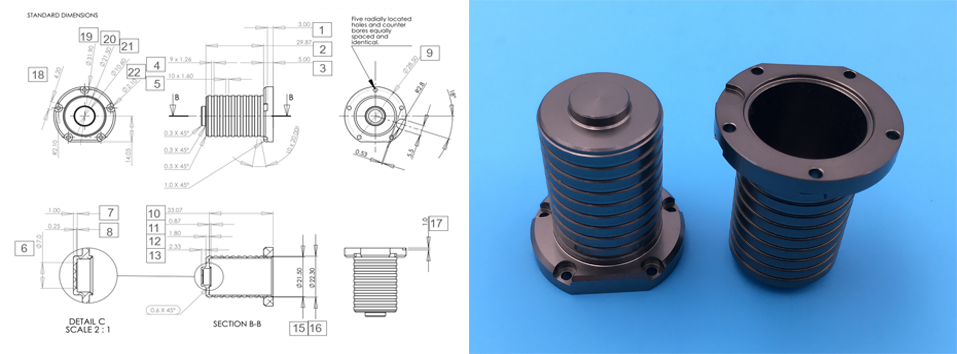

SINO MFG’s CNC milling service is dedicated to creating complex geometries and features on plastic and metal parts for prototypes and low-volume manufacturing. We have more than twenty multi-axis CNC machining centers imported from the United States and Taiwan, as well as domestic automatic and manual mills.

Our CNC milling services are designed to complement our many other fabrication and finishing capabilities, to provide you with a complete and rapid turn-key solution for your next project.

What Is CNC Milling?

Milling is the process of removing material from a solid blank to create a finished or semi-finished shape. The process is guided by your CAD file, optimized to create a physical copy of your digital design.

In CNC milling, the workpiece is held in a rigid vice or holding fixture, mounted on a work table. This table rotates as well as pivots, making two axes of movement. Cutting tools mounted on a rotating spindle remove material to create a variety of complex geometries and part features on the workpiece. The real advantage of a multi-axis milling machine, such as our Haas UMC-750 milling center, is that the worktable and the spindle move on many axes independent to one another, providing not only accuracy and repeatability but also versatility.

The Advantages CNC Milling Service

Imported CNC milling centers and cutting tools offer repeatable precision on your projects.

Staffed by skilled operators working with a team of international managers and toolmakers.

We’re able to keep costs down while providing unmatched precision and quality without compromises.

We work in a clean, well-lit and climate-controlled production area, certified to ISO9001:20015, ISO14001 and BS-OHSAS 18001 standards.

We use best-in-class AutoCAD software for maximum efficiency and machine compatibility.

Incoming quality inspection and testing of raw materials ensures the integrity of our supply chain, so you get exactly the materials you specified.

We are experts in prototyping and low-volume manufacturing, so quick set-ups and rapid production is in our DNA.

Our CNC milling services are designed to work in tandem with our many other in-house fabricating and finishing capabilities, to provide you with a comprehensive one-stop rapid manufacturing solution.

We’re located close to major shipping ports in Shenzhen and Hong Kong, so your parts can be on their way to you fast.

What Kinds Of Material Can Be CNC Milled?

While potentially any solid, stable material can be milled, we have a standard selection of raw material including hard plastics and aluminum, various steels, titanium, magnesium, brass, copper and other alloys.

Note that some hardened steels may be too hard to CNC machine, or else would require specialty cutting tools and longer processing times. Soft elastomers or plastics may also be impossible to mill since they cannot be held in a fixed position or would change in shape under the pressure of the cutting tool.

| Steel, iron series | Stainless steel series | Aluminum series | Copper series | Plastic series | Surface treatment |

| SUM24L | SUS303 | AL1050 | C1020 | PC | Sand blasting |

| SUM23 | SUS304 | AL2017 | C1100 | PP | Anodizing |

| SS400 | SUS316 | AL2024 | CuCr | Nylon | Nickel plating |

| S45C | SUS403 | AL5056 | CuTi | POM | Titanium coating |

| SCM435 | SUS416 | AL5052 | C5191 | ABS | Gold plating |

| SKD11.61 | SUS420J2 | AL6020 | C1220 | PVC | Silver plating |

| SK3、SK4 | SUS430 | AL6061 | C3604 | PEEK | Chrome plating |

| Others | SUS630 | AL6063 | Others | PMMA (Acrylic) | Black oxide |

| Others | AL6082 | PTFE (Teflon) | Polishing | ||

| AL7075 | Bakelite | Chemical grinding | |||

| Others | Others | Others |

Surface finishes

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the CNC machined parts.

| Picture | Name | Description |

|

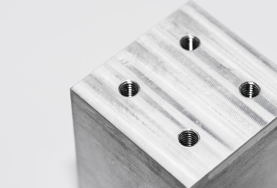

Smooth (as machined) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. |

|

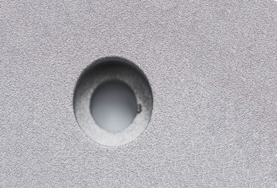

Sand Blasting | Sand blasting adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Mainly used for aesthetic purposes. |

|

Anodized Clear or Color (type II) | Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance. Available in a variety of colors. |

|

Anodized Hardcoat (type III) | Hardcoat anodizing produces a thicker ceramic coating providing excellent corrosion and wear resistance. for functional applications. |

|

Powder Coated | Powder coating adds a thin layer of strong, wear and corrosion resistant protective polymer paint on the surface of a part. Available in a large range of colors. |

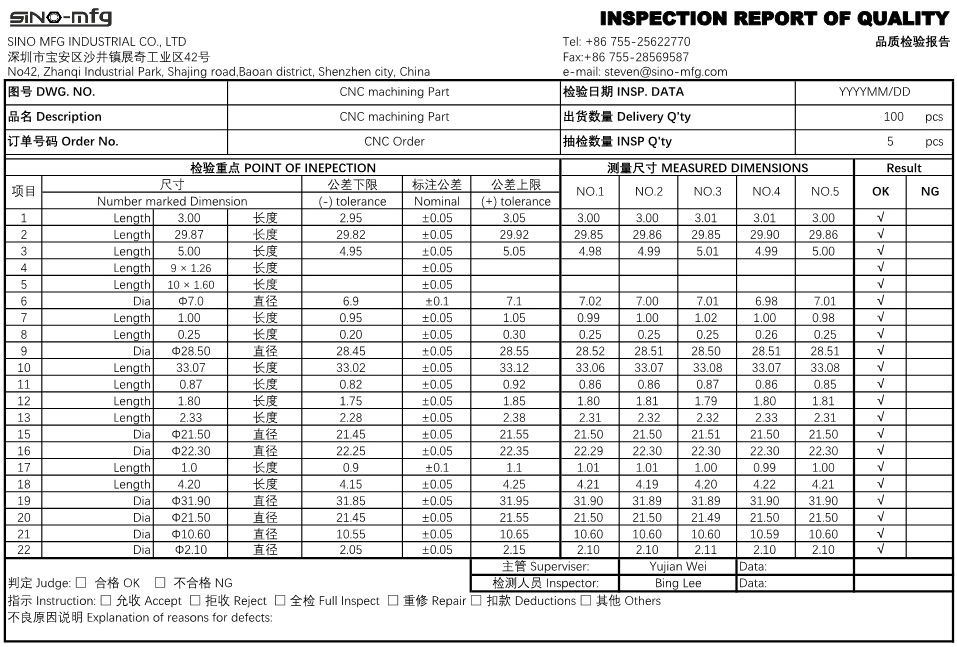

QC report

After the parts have been CNC machined and surface treated, we will use professional QC equipments to inspect the parts and send relevant QC reports according to customers’ requirements.

Please click on our RFQ page for reference on how to request an inquiry. We will provide custom quotation within 12 hours.

Bring your product idea to life as soon as 5 days!

Bring your product idea to life as soon as 5 days!

Bring your product idea to life

as soon as 5 days!