CNC Turning

1-10000 pcs

Metal and Plastic material

3-20 working days

CNC Turning

1-10000 pcs

Metal and plastic material

3-20 working days

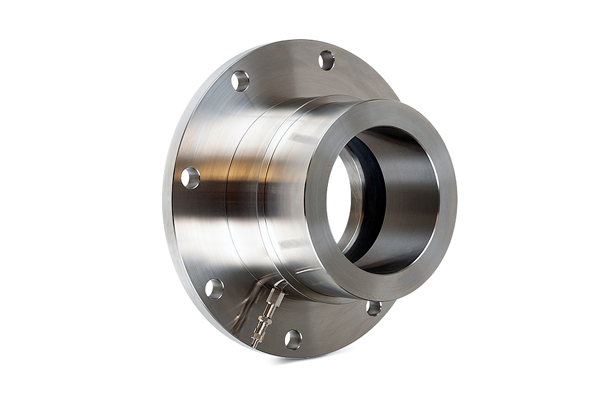

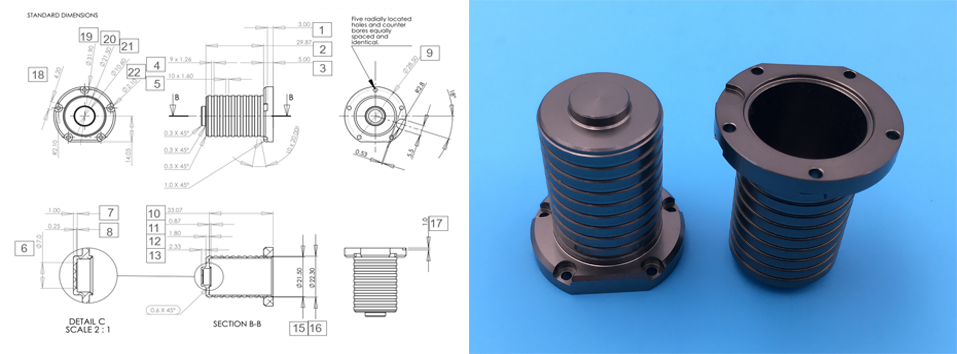

CNC Turning Service

At SINO MFG, we provide you with high quality CNC turning services using our brand-new Haas ST-20Y turning mills imported from the United States. These CNC turning mills are hybrid machines, combining the best features of lathes and mills to provide true 4-axis machining for even greater efficiency and more complex geometries on your project.

When combined with our other rapid prototyping, cnc machining, plastic injection molding and finishing services, you can get great parts for up to 50% less than our competitors while keeping the quality you expect and deserve.

What Is CNC Turning?

Turning involves holding the workpiece in a horizontally-mounted, adjustable spindle. As the workpiece rotates, various cutting tools are applied to the piece to create circular shapes and features like rings, grooves, slots, contours, radii, internal bores and threads. On our Haas turning mills, an extra axis of movement allows us to work perpendicular to the lathe spindle for making square faces or boring holes. This opens up many new machining possibilities.

Turning is used for any rotationally symmetrical shape, to remove material quickly while leaving an excellent surface finish that sometimes requires no post-processing.

Why Choose CNC Turning?

CNC turning is the fastest way to remove large amounts of material on rounded stock. It’s also ideal for larger production runs when coupled with an automatic bar feeder that provides an uninterrupted supply of raw material into the machine.

CNC turning is the only industrial process to choose when making production volumes of concentric shapes or threaded features. And, because of the rigid construction of these machines there is little vibration, which means CNC turning can offer high levels of dimensional accuracy with excellent surface finishes.

What Kinds Of Material Can Be CNC Turned?

While potentially any solid, stable material can be turned, we work with hard plastics and aluminum, various steels, titanium, magnesium, brass, copper and other alloys.

Note that some hardened steels may be too hard to CNC turn, or else will require specialty cutting tools and longer processing times. Soft elastomers or plastics may also be impossible to turn since they cannot be held in a fixed position or would change in shape under the pressure of the cutting tool.

CNC Parts Materials

Through continuous technological innovation and development, we have accumulated a very rich and wide range of various types of metal and plastic materials machining process characteristics and technical know-how. In addition to our stock list, we can provide you with customized raw material as required.

| Steel, iron series | Stainless steel series | Aluminum series | Copper series | Plastic series | Surface treatment |

| SUM24L | SUS303 | AL1050 | C1020 | PC | Sand blasting |

| SUM23 | SUS304 | AL2017 | C1100 | PP | Anodizing |

| SS400 | SUS316 | AL2024 | CuCr | Nylon | Nickel plating |

| S45C | SUS403 | AL5056 | CuTi | POM | Titanium coating |

| SCM435 | SUS416 | AL5052 | C5191 | ABS | Gold plating |

| SKD11.61 | SUS420J2 | AL6020 | C1220 | PVC | Silver plating |

| SK3、SK4 | SUS430 | AL6061 | C3604 | PEEK | Chrome plating |

| Others | SUS630 | AL6063 | Others | PMMA (Acrylic) | Black oxide |

| Others | AL6082 | PTFE (Teflon) | Polishing | ||

| AL7075 | Bakelite | Chemical grinding | |||

| Others | Others | Others |

Surface finishes

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the CNC machined parts.

| Picture | Name | Description |

|

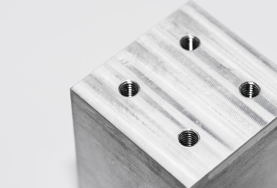

Smooth (as machined) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. |

|

Sand Blasting | Sand blasting adds a uniform matte or satin surface finish on a machined part, removing all tool marks. Mainly used for aesthetic purposes. |

|

Anodized Clear or Color (type II) | Anodizing adds a thin, hard, non-conductive ceramic coating on the surface of aluminum parts, increasing their corrosion and wear resistance. Available in a variety of colors. |

|

Anodized Hardcoat (type III) | Hardcoat anodizing produces a thicker ceramic coating providing excellent corrosion and wear resistance. for functional applications. |

|

Powder Coated | Powder coating adds a thin layer of strong, wear and corrosion resistant protective polymer paint on the surface of a part. Available in a large range of colors. |

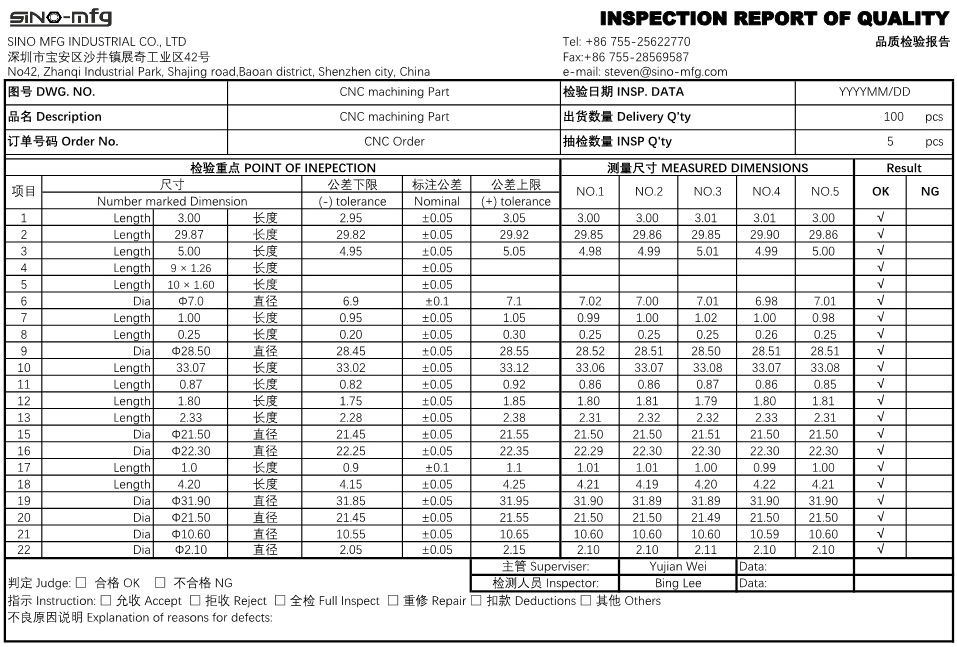

QC report

After the parts have been CNC machined and surface treated, we will use professional QC equipments to inspect the parts and send relevant QC reports according to customers’ requirements.

Please click on our RFQ page for reference on how to request an inquiry. We will provide custom quotation within 12 hours.

Bring your product idea to life as soon as 5 days!

Bring your product idea to life as soon as 5 days!

Bring your product idea to life

as soon as 5 days!